VES DELIVERS ON TIME AND ON BUDGET!!!!!

Completed January 2021 – Pitt ARS received a new advanced aerospace blast and paint booth to enhance their war fighting capabilities.

Project involved an extensive facility upgrade to include: Modification and raising a 36” return duct to accommodate new booths going into building, installation of a new 36” 45-degree elbow, modify building hangers, replaced insulation to match, modify main gas line, added a new gas line valve and gas regulator to accommodate new paint booth, provided and installed all conduit, wire, disconnects, and supports for the dust collection equipment, paint booth, reclamation equipment, air shower, and breathing air compressor, remove hallway man door, and installed a new transition area to accommodate the new NIOSH air shower discussed in walk through, installed new fire suppression to all equipment, installed all roof and wall penetrations to include; duct, curb, support steel, and roof flashing.

New equipment included a new 15’-4” Wide x 17’-8” High x 32’-0” Deep, 19,000CFM AMU Heated Paint Booth:

Construction: 20 gauge insulated pre-coated vertical wall panels white Inside/Blue Outside. Panels have a rigid internal steel frame to provide support for the overhead unit. Factory applied coating is vinyl to help protect against scratching and to increase resistance to water and chemical exposure. Panels use simple joint connection to eliminate gaps and facilitate easy assembly. Ceiling System is bolt together with a white powder coat finish and flanged for bolt together assembly. Ceiling Grid panels use a blanket filter insert with knife edge to seal completely and ceiling grid panels are secured to the top of the wall panels to minimize the possibility of a bad seal. A Vane Axial exhaust fan (19,000 CFM @ 3” sp) (71 dba average) with 15 HP 480v/60/3TEFC motors, an Industrial Filter house stiffened for high negative pressure and complete with high strength filter racks and 3-Stage NESHAP filtration for chromate removal (98% removal at 2 microns), complete NESHAP 3 stage exhaust filtration. Advanced equipment included an Auto-Pressure System Designed to automatically keep the paint booth balanced when in operation. It is required by EPA 6H standards on all positively pressured booths. This system consists of a variable frequency drive that controls the exhaust fan motor with input from a pressure transducer and sensing probes. The system monitors the interior booth pressure and will adjust the exhaust fan RPM’s to what is needed for the volume of exhaust air based on what the incoming intake air is. The result is a booth that is balanced automatically and will stay in balance as the filters load up with paint over spray. System will increase useful filter life, provide a constant airflow through the booth, and the ability to control booth pressure.

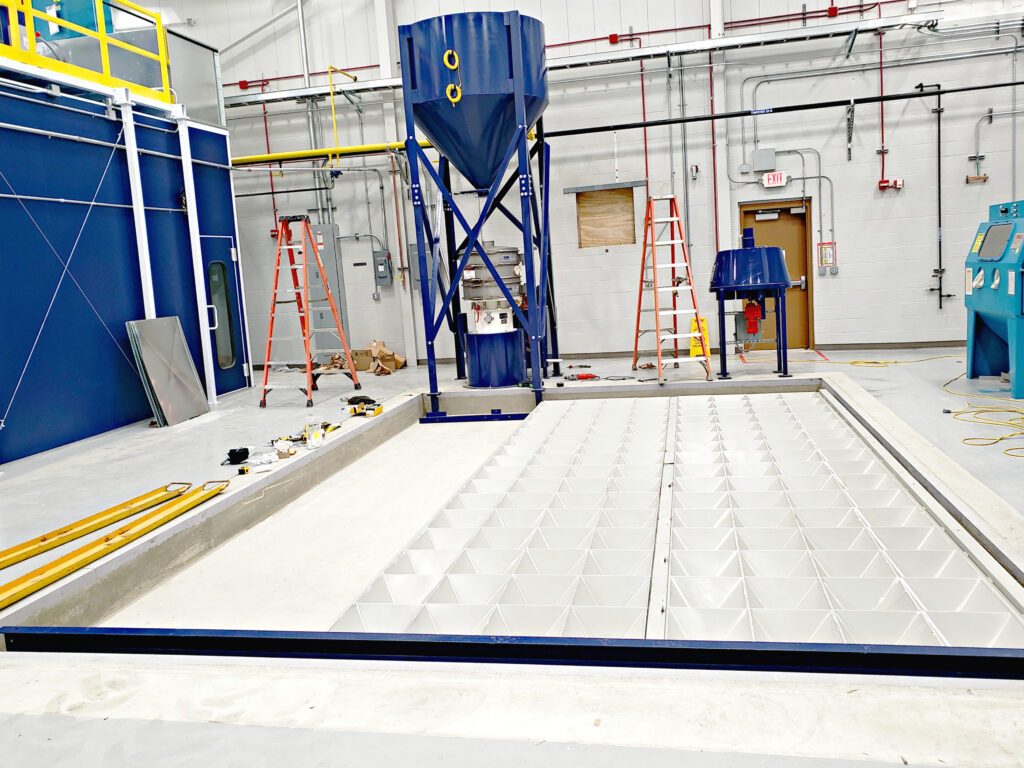

Fully Modular Blast Booth: 15’W x 12’H x 20’L, 12-gauge walls, 14-gauge ceilings, and LED lighting . Construction One set swing styles equipment door and one metal personnel door with view windows and safety interlocks. A 18,000 CFM, Vertical Cartridge Filter Dust Collector. One Twin Operator Blast Machine & Reclaim System (will support simultaneous operation of two blast operators) including a 64 cubic foot clean media storage hopper. VES’ StealthStrip 1/2” bore, silent blast nozzle. Control Panels with disconnect switches, motor starters, and safety interlocks. Two (2) Operator Safety Packages with, CO monitor, breathing air hose, helmet, gloves and aprons. VES’ advanced sealed Heavy Particle Separator System (HPS), 100 cubic foot Initial Recovery Hopper, Level Sensor for bulk hopper overfill protection, the industries most Powerful and Self-Cleaning Rare-earth Magnetic Separator, Ionizer – To reduce media static build-up, 30” Vibratory Separator, a single stage aluminum oxide fluidized bed, a below grade, guaranteed clog free, full floor pneumatic recovery system with; a fully automatic and programmable gatling rotary style selector, two Precision-Drive Media Control Valves for superior control when stripping sensitive composite and metallic substrates.

Clothes Cleaning Systems NIOSH built personnel air blow-down chamber including, a new 240 Gallon Receiver Tank, 3 hp exhaust blower, VFD (variable frequency drive), and HEPA & HEPA Pre-Filters

Sullair Oil-less Breathing Air Compressor: Including a Non-Cycling Refrigerated air dryer, Particulate and Coalescing filters, 240 gallon ASME receiver tank, Nano NBA-90 Breathing Air Purifier, and all equipment included automatic electronic timed drains

See below the pictures from manufacturing, delivery, facility modifications, to installation.