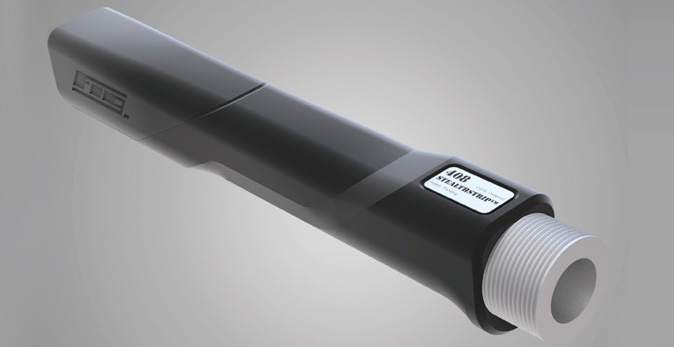

StealthStrip™

StealthStrip™ Quiet Abrasive Blast Nozzle

An innovative approach to reducing hazardous sound exposure while maintaining strip rate. Through a combination of advanced computational modeling, laboratory analysis, and rigorous testing performed in the blasting environment we have designed StealthStrip™, an advanced, ultra-low noise abrasive blast nozzle with improved worker productivity and ergonomics.

StealthStrip™ reduces hazardous noise by as much as 11dB over similar nozzles, and is designed as a drop in replacement for a standard #8 long-venturi nozzle with similar size, weight, and strip rate. As a result, the StealthStrip™ nozzle will be half as loud as conventional nozzles.

Hazardous Noise

Workers in blasting environments are routinely exposed to hazardous levels of noise, producing hearing loss and tinnitus over time. Workers with noise induced hearing loss suffer from increased frustration, loss of concentration, anxiety, loss of sleep, and lower workplace effectiveness. In addition, OSHA monitors workplaces and issues fines for high-levels of hazardous noise. Long term health costs and legal claims by injured workers are also a major source of lost revenue.

Hearing protection alone is not enough to prevent injury to workers. The damaging noise levels in a blasting environment are so high that they can conduct through a person’s bones and continue to cause injury regardless of the hearing protection used. To successfully reduce noise you must attack the source of the noise: the blast nozzle.

Features

• Reduction in hazardous noise by 11dB(A)

• Strip rate comparable to standard nozzles

• Ergonomic design for operator comfort

• Drop-in replacement for existing abrasive blast equipment

Benefits

• Reduced incidence of worker hearing damage

• Lower lifetime healthcare costs

• Increased workplace productivity

• Reduced operator frustration

• Reduced OSHA noise citations

Contact our sales department to see how our nozzle can work for you.