Dust Mitigation Mapping (DMM)

Dust and Aerosol Migration Mapping (DMM)

Figure Engineering has developed a technology that makes monitoring of aerosol contaminants reliable and meaningful. Dust and Aerosol Migration Mapping (DMM) is an engineering service that measures, analyzes, and characterizes respirable hazardous dust and aerosol movements within closed environments. This allows for rapid visualization of migration pathways, stress-free management-of-change, and simple spot check monitoring for long-term maintenance.

Technical Summary

Chromium dust is 8x more likely to cause cancer than asbestos. Hazardous dusts containing chromium and cadmium are generated during common industrial processes, including media blasting, grinding, sanding, and welding, and migrates far from the source. Swipe sampling and other conventional dust migration measurement methods are frustratingly unreliable and unhelpful for dust exposure mitigation.

Figure Engineering’s Dust & Aerosol Migration Mapping™ technology makes migration measurement reliable and meaningful. The result is rapid visualization of migration pathways, stress-free management-ofchange, and simple spot check monitoring for long-term maintenance.

Dust & Aerosol Migration Mapping can satisfy OSHA requirements for remedial action following a citation and can proactively protect Voluntary Protection Program status.

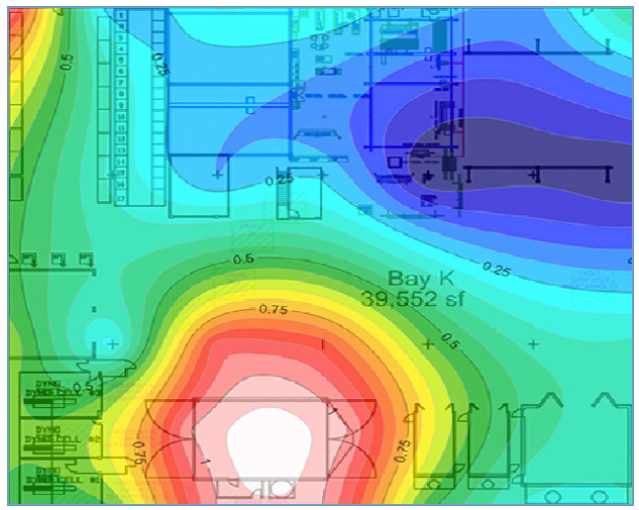

This dust migration map pictured above shows the extent of a known primary dust source (lower center) and identified an unknown secondary source in a welding cell (upper left).

Operational Capabilities

Dust & Aerosol Migration Mapping™ is an engineering service that measures, analyzes, and characterizes respirable hazardous dust and aerosol movement within closed environments.

Dust & Aerosol Migration MappingTM can:

- Characterize dust and aerosol migration

patterns for hazardous materials, such as:- Chromium

- Cadmium

- Beryllium

- Lead

- Volatile Organic Compounds (VOCs)

- Detect dust migration pathways

- Identify unknown hazardous generators

- Provide empirical data for management-of

change evaluation - Provide long-term process control

- Help establish regulated area boundaries

- Satisfy OSHA requirements for remedial

action following a citation. - Protect VPP status