SoluStat

SoluStat™ Advanced Stripping Solution Control

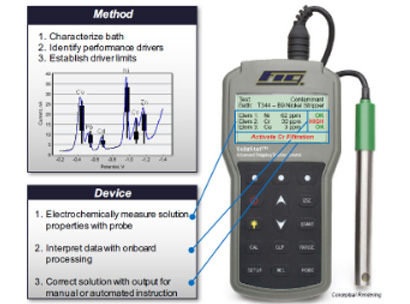

VES and Figure Engineering are developing an innovative method for characterizing metal finishing solutions and a portable device for measuring, interpreting, and correcting bath solution performance drivers. The method and device bring laboratory analytics to the production line and bridge the longstanding gap between human interpretation and machine automation.

Technical Summary

Normal degradation of stripping bath performance leaves production crippled.

Slow and inconsistent strip rates, unscheduled line shutdowns, substrate corrosion investigations, and part condemnation can be avoided with a novel technology that characterizes bath solutions and provides non-expert users real-time bath performance feedback. Current technologies require a high degree of skill to operate and cannot provide onboard data interpretation or generate human or machine instructions for bath correction.

Figure Engineering is developing an innovative method for characterizing stripping bath solutions and a portable device for measuring, interpreting, and correcting bath solution performance drivers.

The method and intuitive device bring laboratory analytics to the production line and bridge the longstanding gap between human interpretation and machine automation.

Operational Capabilities

Phase II developments will yield processes and a device that can characterize, measure, interpret, and correct stripping solutions. The novel technologies will:

- Characterize four problem baths at Tinker AFB for:

- Substrate Loss Rate; temperature corrected [±0.1 mil/hr]

- Coating Strip Rate; temperature corrected [±0.1 mil/hr]

- Critical Contaminants; top 3 performance drivers per bath [±1ppm]

- Provide Tinker AFB analytic lab with supplemental data for current routine bath health monitoring program.

- Reduce Tinker AFB analytic lab monitoring burden.

- Prevent substrate corrosion attack

- Troubleshoot suspected substrate corrosion attack.

- Predict bath life to allow adequate maintenance or replacement planning

Development Objectives and Milestones

During the SBIR Phase II effort Figure Engineering will:

- Develop a method to characterize a broad range of inorganic stripping baths

- Demonstrate the characterization method on four problematic plating and thermal spray stripping solutions at Tinker AFB

- Develop a device for use in the Tinker AFB analytics lab to supplement the current bath health monitoring program for the four baths.

- Demonstrate and document prototype capabilities.

- Develop a strategy to integrate tank-mounted devices into the Allen Bradley ControlLogix®-based* tank health monitoring system [*RFP W912BV-15-R-0093, PMXG Plating Shop Renovation, Building 3001, Tinker AFB]

Government and NDIB Applications

Applications

- Controlling bath solutions for reliable stripping of plating, plasma, and thermal coatings

- Precision plating of exotic ternary alloys: microactuators for insectsized devices, aural implants for rehabilitation or combat communications, RF antennas

Target Customers

- Aircraft, automotive, and industrial manufacturers and maintenance, repair, and overhaul (MRO) facilities

- Boeing Company (letter of support)

- Army Aviation & Missile Life Cycle Mgmt (AMCOM) (verbal support)

- Consumer electronics industry